Supply Chain

Supply Chain Management¶

Three broad levels¶

- Strategic Level SCM takes in the entire scope of a company's supply chain network and processes. It addresses the major long-term elements in a comprehensive strategy, including the type and number of facilities, technologies and suppliers.

- Tactical Level nails down the specific means of executing the strategy, be they production schedules, logistics processes, contracts or software applications. Time horizons are shorter than in strategic SCM. Here's where standards and best practices are identified for key deliverables such as customer service, efficiency and cost.

- Operational Level encompasses the daily operations of SCM. Forecasting, production scheduling, shipping and invoicing are typical operational tasks.

Data Science in Supply Chain¶

PREDICTING SUPPLY DISRUPTIONS¶

Supply chain data analytics gives companies the ability to predict supply disruptions and make adjustments before problems impact production. Companies can also look at trending data on weather events, political instability, or financial issues that may impact a supplier’s ability to deliver on schedule. With this information, teams can make alternate plans as needed so they can maintain normal operations.

QUALITY ASSURANCE¶

Manufacturing companies use real-time data analysis for quality assurance. Using IoT-enabled cameras and measuring devices, a manufacturer can identify issues before a product is shipped to retailers or consumers.

WAREHOUSE MANAGEMENT¶

Information gathered on warehouse temperature, shelf weight, and load weight can be used to optimize warehouse operations and improve productivity. Analytics can inform receiving, tracking, and storing inventory, as well as workload planning, managing shipping, and monitoring the movement of items in the warehouse.

LOGISTICS¶

Data analytics is used in logistics to plan more efficient delivery routes and reduce fuel consumption. Companies can use data to identify the ideal mode of transportation for their loads.

SALES, INVENTORY, AND OPERATIONS PLANNING¶

Retailers can analyze point-of-sale (POS), inventory, and production volume data to identify misalignment in supply and demand. As a result, they can determine when to place orders with suppliers, which products to put on sale when, and when to launch new product offerings.

Demand planning¶

Demand planning is a process for gathering historical data, such as past sales, and applying analytics and statistical modeling to create a forecast or demand plan that the sales department and operational departments -- for example, manufacturing and marketing -- can agree on. The forecast determines the types and quantities of products to be manufactured. Getting the forecast right is critical for avoiding costly problems such as the bullwhip effect, in which small fluctuations in retail demand are magnified further up the supply chain, leading to severe shortages or surpluses of inventory.

Production planning¶

Production planning,the company nails down the specifics of where and how the products called for in the demand plan will be manufactured. A more fine-tuned variation called advanced planning and scheduling & optimization seeks to optimize the resources that go into production and make them more responsive to changes in demand.

Material requirements planning¶

MRP is used to ensure sufficient materials and components, such as subassemblies, are available for use in the manufacturing process by taking inventory of what's on hand, identifying gaps, and buying or making the remaining items. The central document in both MRP and production planning is the bill of materials (BOM), a complete list of the items needed to make a product. MRP is sometimes done as part of manufacturing resource planning (MRP II), which broadens the MRP concept to other departments such as HR and finance.

Inventory management¶

Inventory management consists of various techniques and formulas for ensuring adequate supply -- from raw materials in a manufacturing plant, perhaps managed in an MRP system, to packaged goods in a retail store -- for the least expenditure of time and resources.

Manufacturers are faced with a variety of inventory management issues, many of which involve coordinating demand planning with inventory at both ends of the production process. For example, sometimes MRP leads to more inventory -- especially when the system is first implemented -- and the manufacturer must work to synchronize MRP parameters with the inventory already on hand.

Procurement¶

Sometimes called sourcing, procurement is the process of finding suppliers for goods, managing those relationships and acquiring the goods economically -- along with all the communication, such as sending out requests for bids, and paperwork, including purchase orders and invoices.

-

Strategic sourcing is an elevated and more sophisticated type of procurement that aims to optimize a company's sourcing process by taking advantage of its consolidated purchasing power and aligning it with business goals.

-

Supplier relationship management (SRM), in contrast, addresses sourcing issues by focusing on the suppliers the company deems most critical to success and systematically strengthening relationships with them while fostering optimal performance.

Logistics¶

Logistics covers the transporting and storing of goods, from the delivery of parts and raw materials to manufacturers or processors to the delivery of finished products to stores or direct to consumers, and even beyond for product servicing, return and recycling -- a process called reverse logistics. Inventory management is threaded throughout the logistics process.

Goals of SCM¶

- cost savings from acquiring goods and services as cheaply as possible and minimizing expenses on capital goods, such as inventory, facilities and equipment;

- efficiency that comes from avoiding waste and duplication;

- revenue increases from meeting higher levels of demand with sufficient supply;

- profit from lower costs and higher revenue;

- customer satisfaction from balancing supply and demand, and delivering the products consumers want;

- quality improvements from sourcing better materials, avoiding production errors and gathering customer feedback; and

- stability from effective risk management, visibility and collaboration.

- better relationships with suppliers, distributors and retailers;

- improved brand image;

- environmental sustainability;

- improved cash flow;

- safer products and services;

- lower overhead;

- improved accountability and compliance; and

- more innovation.

Softwares and Tools involved in SCM¶

- Basic Stuff : APS, demand management, inventory management, MRP, production planning, procurement and sourcing, S&OP and SRM.

- Order management systems designed to integrate the workflow of customer orders from receipt to fulfillment and payment.

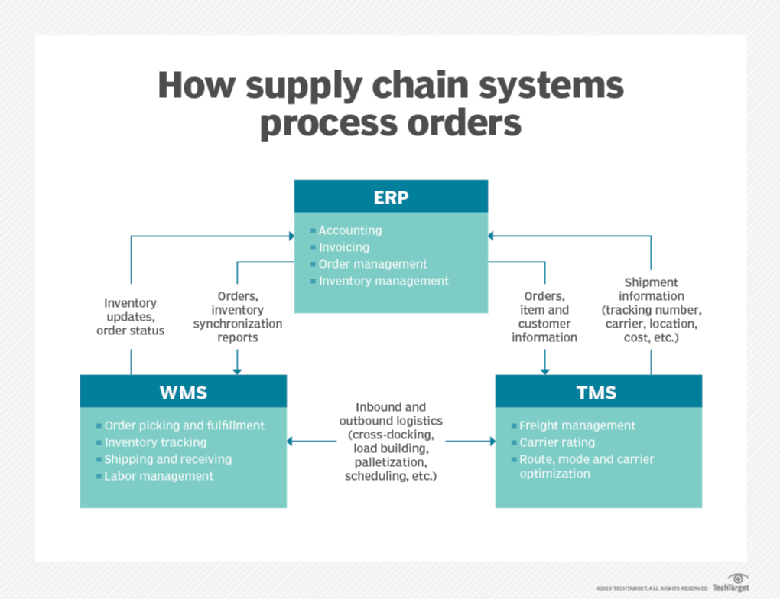

- Transportation management system** is essentially a repository of detailed information about shipping carriers that enables users to plan, execute and track shipments.

- ****Warehouse management system**** is software for managing the many processes involved in moving goods through warehouses, such as inventory tracking, receiving and putaway.

Sources of Supply Chain Alternate Data¶

- Trade (Shipping) Data: Shipping/Trade data is a collection of information on ships, cargo, owners, shipbuilders, movements, fixtures, causalities, ports, and companies. Shipping data is perhaps the most obvious and widely-used dataset category to consider when undertaking supply chain analysis. Trade data comes from government import/export data and bill of lading data at the port level. The coverage typically includes all products and commodities shipped globally. These products and commodities can frequently be tied back to individual companies or rolled up for sector insights.

- Satellite Data: Satellite data provides information on both commodities and manufacturing plants where products and materials are traveling from, but also offers information on vessel movements and port activity for shipping data. Satellite data can be harnessed for supply chain analysis to make better choices, anticipate issues, and re-route material flows to minimise disruption. For investors, satellite data is most valuable for tracking sea freight. The value of satellite data relative to import/export data provided by trade data is that the data is more timely – often real-time. It’s possible to see in real-time if a vessel is stuck at a port like LA and how many ships are floating offshore

- Flight Data: Flight data provides end-to-end information on cargo and the movements of aircraft through alerts and tracking. Flight data, specifically as regards cargo traffic, can be valuable for analysing supply chain dynamics for higher value or time-sensitive goods such as pharmaceuticals, tech, and luxury goods, or items that need to be expedited. However, unlike sea freight discussed previously, it’s not possible to see “inside the container” for air freight so it’s not always clear what is being shipped.

- IoT & Geolocation: IoT devices allow companies to understand where goods are, how they are being stored, and when they can be expected at a specific location. For Ex: authenticating the location of goods in real-time, tracking speed of movement, monitoring of storage conditions, streamlining the movement and location of goods, and validation of arrival.

- Other Data for Supply Chain Tracking: Other datasets worth exploring in the context of supply chain analysis are credit datasets, ESG datasets, firmographic and reference data, NLP on public text data, and crawled data for analysis of stock-outs at online retailers.

Supply Chain Planning¶

- Demand Planning

- Inventory Optimization

- Merchandise Financial Planning

- Network Design

- Production Planning

- Sales & Operations Execution

- Sales & Operations Planning

- Allocation & Replenishment

- Supply Planning

Supply Chain Execution¶

- Transportation Management

- Logistics Network

- Modeling

- Warehouse Management

- Labor Management

- Robotics Hub

- Warehouse Tasking

Omni‑Channel Commerce¶

- Assortment Management

- Inventory & Order

- Lifecycle Pricing

- Space & Floor Planning

- Store Execution

- Workforce Management

- Merchandise Operations

Problem Statement

In the wake of a swiftly globalising market, Supply chain processes are facing a multitude of complications with respect to routing, resources and planning. Transportation vehicle schedules are becoming increasingly difficult to determine, and resources are often wasted when orders are under- or over-supplied. Inventory management is becoming inefficient and overly costly as customers increase their demand for on-time delivery and accurate tracking. Supply chain operations are experiencing significant issues due to a lack of automated tools integrated into their process to effectively manage planning, forecasting and optimisation of resources.

Solution and Services

The use of Machine Learning technology offers a viable solution to many of the problems plaguing supply chain operations. AI algorithms can be used to automatically detect inconsistencies, predict changes in customer orders, and ultimately increase operational efficiency. Machine Learning technologies can enable companies to improve their inventory management systems by accurately forecasting demand, optimising routing, and adjusting vehicle schedules. Automation technology also enables companies to develop new technologies to maintain better shipment tracking capabilities and accurate inventory forecasts.

To properly and effectively employ Machine Learning technologies in the supply chain, companies must optimise the technologies through algorithms and models. They must use the data collected from their supply chain operations to generate sets of rules that can accurately predict and optimise the performance of their operations.

In addition, Machine Learning technology is well-suited to integrate customer data with production data to provide better insight into customer preferences and needs. Companies can develop customer models that can accurately predict customer desires and behaviours, which can allow the company to adapt their product offering and operations to meet these customer needs. Machine Learning technologies can also provide companies with faster customer feedback, enabling them to monitor customer satisfaction and make more informed decisions about their operations.

By leveraging Machine Learning technologies, companies can reduce cost and improve the efficiency of their supply chain operations. With the power of automation, companies can avoid unnecessary expenses, better coordinate resources, and ultimately increase their customer satisfaction and optimise return on investments.

From predictive analytics to predicting customer demand and even planning shipping routes, machine learning can help make the supply chain smoother and more productive. Here are a few specific ways machine learning can be used to transform supply chain operations:

-

Demand forecasting: By leveraging the power of predictive analytics, machine learning algorithms can be used to accurately forecast customer demand and anticipate changes in the industry. This helps companies better plan for future supplies, adjust their supply chain strategies, and stay ahead of their competitors.

-

Transportation planning: By leveraging real-time data, machine learning algorithms can be used to optimise transportation routes and reduce costs. With smarter routing, companies can save time and money by optimising the delivery of goods and services.

-

Inventory optimisation: With machine learning, it’s now possible to anticipate when to order inventory and which products to carry. This can help businesses reduce stock-outs and keep inventory costs low.

-

Quality control: Machine learning algorithms can help companies improve product designs and bolster manufacturing processes. This ensures that the highest-quality parts are produced, ensuring customer satisfaction and reducing the need for product returns.

Conclusion: The efficient operation of a company’s supply chain is essential for the company to thrive in today’s global economy. By employing Machine Learning technologies, companies can improve processes and integrate analytics to reduce costs and increase the efficiency of their supply chain operations. Through automation technology, companies can reduce their inventory management efforts, enhance customer feedback processes, and ultimately increase the accuracy of their supply chain operations. With Machine Learning, companies can be better equipped to meet customer needs, save time and money, and increase their ROI.

| a. | Inventory planning |

|---|---|

| b. | Sales Forecasting |

| c. | Price Forecasting (Change: When & How Much) |

| d. | Replenishment Forecasting |

| e. | Return Forecasting |

| f. | Stock Out Calculation |

| g. | Markdown Forecasting |

| h. | Estimated Delivery Date and Location |

| i. | Processing Time Estimation |

| ii. | Transit Time Estimation |

| i. | Availability |

| j. | Safety Stock |